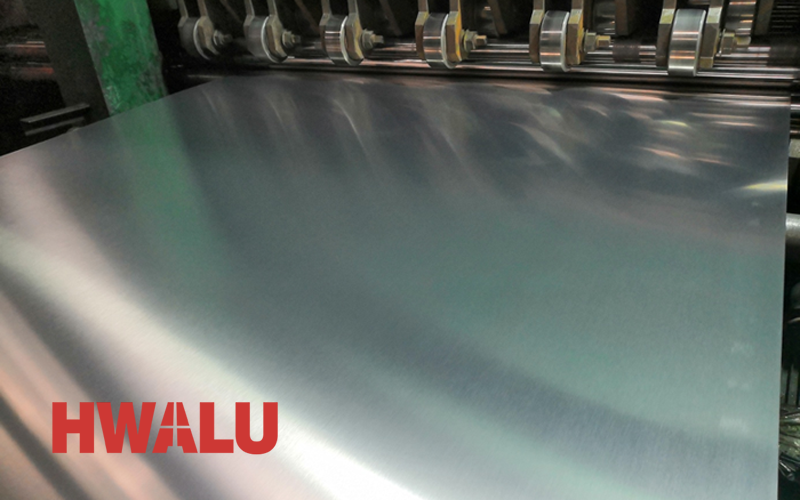

The kraft paper embossed stucco 4x8 aluminum sheet roll is made of kraft paper as a processing material, and the kraft paper is firmly bonded to the stucco embossed aluminum sheet by high temperature and high pressure. Commonly used materials are 1060, 1050, 3003, 5052 aluminum, and tempering is H14, H24, H16, H18, etc. The thickness range is 0.1-3.0 mm, and the thickness of kraft paper is 10-15 microns. Because kraft paper has good ductility and strong moisture resistance, in the thermal insulation industry, kraft paper stucco embossed aluminum is favored by users because of its good corrosion resistance and excellent value preservation.

There are two processes for coating kraft paper on stucco-embossed aluminum:

1: Bonding with glue, the surface of the kraft paper is self-bonding, the advantages of this method are high production efficiency, prompt delivery, low production cost, and the daily output can reach 30 tons. The disadvantage is that due to temperature changes, the surface of kraft paper is prone to bubbles, which affects the bonding effect, and the storage time in the open air should not be too long.

2: Bond the kraft paper and the stucco 0.75 Aluminum Plate together by heating. The advantage of this product is that it has high adhesion, and the water immersion test does not open the glue for 24 hours and does not fall off. The weather resistance is extremely high, and the kraft paper is not affected by temperature changes. The disadvantage is that the production efficiency is slow and the production cost is too high.

- FAVORILERIM

- Web sayfası bildirimcisi

- EXPLORE

- Sayfalar

- Gruplar

- Events

- Blogs

- Marketplace

- Offers

- Jobs

China paints aluminum panels with kraft paper | Huawei

Posted 2022-09-28 02:28:25

0

1756

Record

Recording 00:00

Commenting has been turned off for this post.

Kategoriler

Read More

entirety of the life cycle of the Madden 23 News

This information originated from what those people shared with me. These realizations came about...

This update for Lost Ark Under the Arkesian Sun includes a number of other enhancements in addition to the most recent patch notes the release date and new features

It was stated in a post that was made on the official Lost Ark Gold store blog that the...

MVDs: Tennessee Version

Your self wear't escape Neyland Stadium with a resounding victory and not lined inside of mustard...

How to weld galvanized pipe?

Now many industries will use galvanized steel pipe, because this material is more convenient to...

A Strategy That Can Be Utilized in Order to Conquer the Fallingstar Beast That Is Residing Inside of the Elden Ring

This optional boss, who can be found in the Town of Sorcery to the north of Sellia, presents...